The Greatest Guide To American Plastics

Table of ContentsA Biased View of American PlasticsAn Unbiased View of American PlasticsThe Best Guide To American PlasticsAmerican Plastics Fundamentals ExplainedAmerican Plastics - Truths

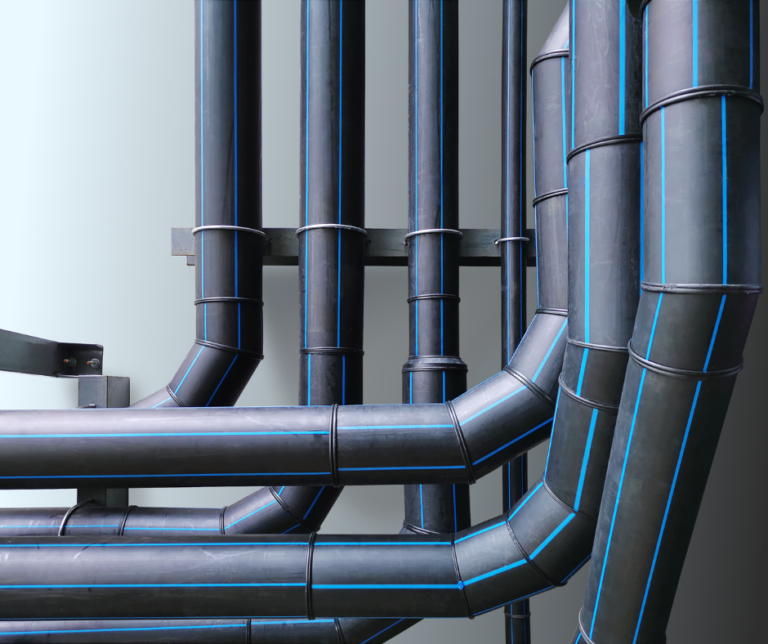

Understanding these elements will enable you to make educated decisions when choosing one of the most suitable pipe for your task. The product make-up of the HDPE pipe plays a crucial function in establishing its PSI rating. HDPE pipes are made from high-density polyethylene, a thermoplastic understood for its stamina and resilience.Different qualities of HDPE may have differing PSI rankings, so it is vital to consider the material make-up when selecting a pipe for your certain requirements. The size of the HDPE pipeline is another essential element that influences its PSI rating. Larger size pipes usually have higher PSI scores, as they have extra material and area to stand up to pressure.

The wall surface thickness of an HDPE pipe also affects its PSI rating. Thicker wall surfaces offer increased strength and resistance to stress, allowing the pipeline to handle greater PSI degrees. Conversely, pipes with thinner wall surfaces may have lower PSI scores and are ideal for applications with lower stress requirements. The temperature level at which the HDPE pipeline will operate is a crucial consideration when identifying its PSI rating.

It is important to take into consideration the maximum operating temperature of the pipe and pick a PSI score that can handle the anticipated temperature level array - https://profiles.delphiforums.com/n/pfx/profile.aspx?webtag=dfpprofile000&userId=1891266661. The PSI ranking of HDPE pipes is determined through strenuous testing and certification procedures. Recognizing how these scores are identified will supply you with self-confidence in the accuracy and reliability of the selected pipeline

Getting My American Plastics To Work

Organizations such as the American Society for Testing and Materials (ASTM) and the International Company for Standardization (ISO) have developed details tests to evaluate the performance and toughness of HDPE pipelines. These tests action aspects such as ruptured pressure, tensile strength, and lasting hydrostatic stamina to determine the ideal PSI ranking.

The stress at which the pipeline bursts establishes its maximum PSI rating, indicating the stress it can stand up to without failure. Long-term hydrostatic stamina testing assesses the pipe's ability to stand up to stress over a prolonged duration.

HDPE pipelines with greater PSI rankings are naturally extra resilient and resistant to deformation under pressure. hdpe pipe supplier in Texas. Selecting pipelines with greater rankings ensures they can endure unexpected pressure rises or outside loads, reducing the danger of pipe failure and the requirement for frequent replacements. HDPE pipes with higher PSI rankings frequently have enhanced resistance to ecological elements such as UV radiation, chemicals, and abrasion

The Main Principles Of American Plastics

By picking HDPE pipelines with greater PSI scores, look at here now you can ensure the safety of your system and personnel. These pipelines are built to deal with high-pressure scenarios, minimizing the risk of leakages, bursts, and various other unsafe cases that can threaten individuals or property. Buying HDPE pipes with higher PSI scores may call for a greater ahead of time cost, however it supplies long-lasting price savings.

These pipelines guarantee the secure and reliable circulation of safe and clean water from the resource to the customer. HDPE pipelines with ideal PSI ratings are widely used in gas distribution networks. They can safely deliver all-natural gas or various other gases from the resource to residential, commercial, and industrial parks, making certain trustworthy and efficient gas supply.

Unknown Facts About American Plastics

They can handle the pressure needed for effective irrigation and watering of grass, yards, parks, and sports areas (custom hdpe pipe manufacturing Midland TX). HDPE pipes with high PSI rankings are ideal for moving numerous industrial chemicals. They can take care of the stress requirements and stand up to chemical rust, making sure the secure and reliable transportation of chemicals in commercial setups

Correct installation is critical to make the most of the efficiency and long life of HDPE pipelines. Adhere to these standards when mounting HDPE pipes with details PSI rankings.

Select the suitable jointing approach based on the PSI score of the HDPE pipeline. Select installations and devices that are suitable with the PSI score of the HDPE pipe.

American Plastics Fundamentals Explained

After installment, perform stress testing to ensure the integrity of the HDPE pipe system. Adhere to industry requirements and guidelines to conduct the proper pressure tests, such as hydrostatic or pneumatically-driven testing, to verify the system's ability to handle the necessary pressure. Proper backfilling and compaction around the installed HDPE pipelines are crucial to give stability and protect the pipes from exterior lots.